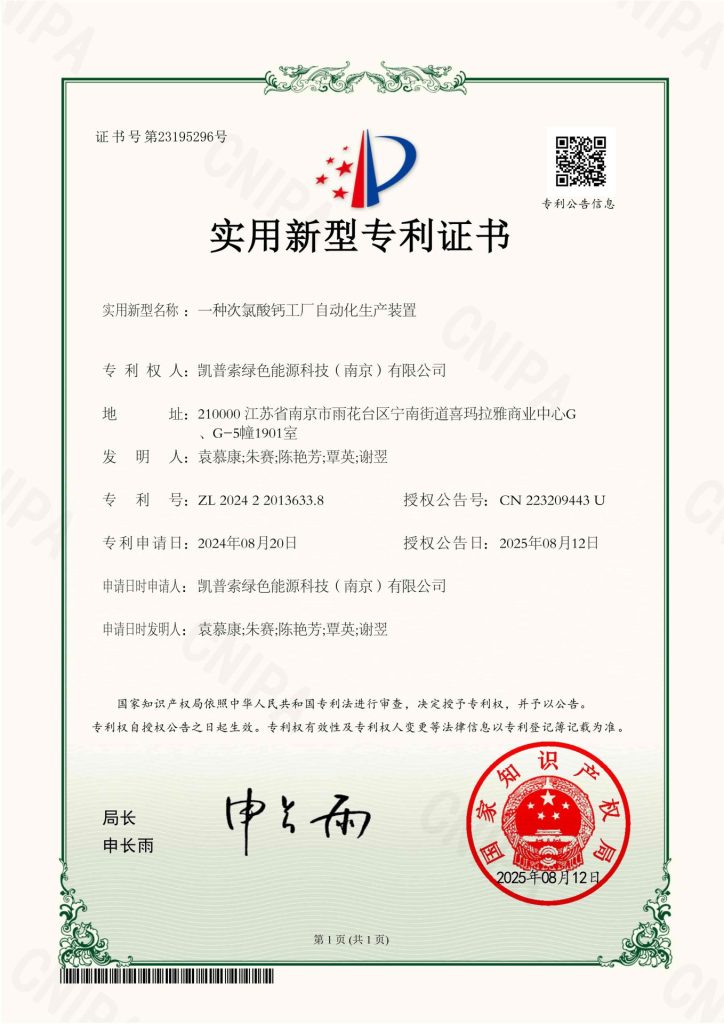

最近、LUVAは「次亜塩素酸カルシウム工場リアクターの全自動制御方法」の特許を取得し、全リアクターの遠隔自動運転を可能にした。この技術革新により、現場オペレーターの数を減らし、被曝リスクを低減し、生産効率を大幅に向上させることができる。

このような背景の下、LUVAは次亜塩素酸カルシウム反応器の遠隔自動運転を実現する先進的なソリューションを開発し、重量ベースおよび手動制御方法の限界を克服した。この新システムの主な利点は以下の通り:

-

リアルタイムのモニタリング: 流量計、ORP分析計、レベルセンサー、温度センサーがリアクターの状態を継続的に追跡する。

-

全自動化: 吐出バルブ、攪拌機、ポンプ、遠心分離機、その他の機器の自動制御により、プロセス全体を通してシームレスな操作が可能になる。

-

インテリジェントなプロセス制御: プログラムされたロジックは、自動トリガーと操作の遅延調整を確実にし、手動介入を減らし、システムの安定性を向上させる。

-

ダイナミックな温度調節: 冷却、加熱、または冷媒の流量は、反応器の温度に基づいて自動的に調整され、最適な反応条件を維持します。

LUVAは、次亜塩素酸カルシウム製造プロセスのインテリジェントなアップグレードを推進し、技術革新にコミットし続けています。マルチパラメーターモニタリングと完全自動制御により、この技術革新は安全で効率的かつスマートなリアクター運転を実現します。今後もLUVAは技術革新を中核に据え、お客様により効率的で安全かつインテリジェントな化学生産ソリューションを提供していきます。

*LUVA:KAPSOMの完全子会社